Hydrogen Energy Projects

P&E Lowlands coordinates and develops small-scale hydrogen energy projects that turn clean hydrogen into real, local power. Together with leading gas and technology partners, we design and implement systems that combine production, storage and fuel cell generation into safe, functional energy networks under 100 kW.

From Green Hydrogen to Local Power

Clean energy only works when all parts connect. P&E Lowlands brings together fuel cell technology, electrical integration and safety engineering into complete hydrogen systems that deliver real power where it’s needed.

Fuel Cell Power Generation

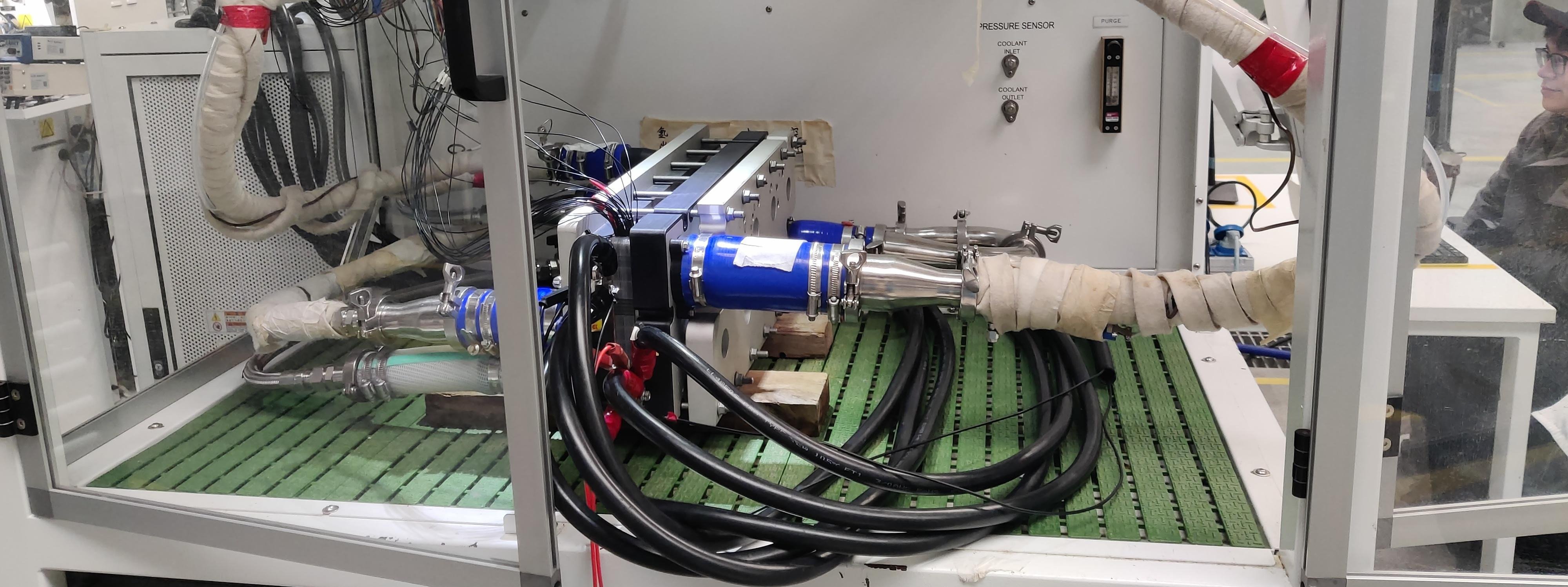

Our modular PEM systems convert hydrogen directly into electricity and heat through a silent electrochemical process. Designed for dynamic loads, each unit maintains high efficiency even during rapid demand changes.

We integrate these systems into DC or hybrid networks, including battery buffers and grid interfaces, ensuring smooth power flow and stable operation.

Behind the simplicity lies detailed engineering:

• Piping and Instrumentation Design (P&ID) that defines hydrogen flow, venting, purging and isolation logic.

• Pressure relief, leak detection and ventilation systems built to class standards (DNV, BV, ISO 19880).

• Control and communication via PLC and CAN networks for temperature, flow and stack diagnostics.

• Electrical interfacing with inverters, converters and shore supply, fully documented and tested.

Each installation is pre-assembled, validated and supplied with detailed commissioning procedures, allowing local teams to connect safely and operate confidently under clear guidelines.

Hydrogen Storage & Safety Integration

Hydrogen storage is never one-size-fits-all. Each project demands the right balance between pressure, capacity, footprint and logistics — and that’s where our engineering makes the difference. Together with our specialised partners in gas and energy systems, we design hydrogen supply concepts that are stable, scalable and safe to operate.

Depending on the application, storage can take many forms: fixed installations for onshore or vessel integration, mobile units for temporary or flexible power setups, or swap systems that allow rapid refuelling between operations.

For compressed hydrogen, we integrate Type IV composite cylinders with certified valves, pressure regulation and class-approved venting systems. For compact or stationary applications, solid-state metal hydride modules provide low-pressure storage with high volumetric density and simplified safety management.

Every setup is monitored through a central control system that tracks pressure, temperature and hydrogen flow. Venting, isolation and leak detection are built into the design from the start — not added later.

The result is a stable, maintainable hydrogen supply that fits your operation, whether mobile or fixed, modular or permanent — ready to keep clean energy flowing, safely and efficiently.